Description

Typical Applications:

- Data Storage

- Flat panel displays

- Optical coating

- Large area coating

- Fusion experiments

- Space simulation

- Load locks and transfer chambers

Technical Features:

- Robust rotor design

- Installation in any orientation

- Highest pumping speed and highest throughput

- Oil-free pump for generating clean high and ultra-high vacuum conditions

Advantages to the User:

- Easy to integrate into complex vacuum systems

- High productivity

- Low operating costs

- Highly reliable operation

Our TURBOVAC rebuild/repair service includes:

- Complete cleaning of the pump

- Replacement of all O-rings, seals, and ceramic bearings

- The pump is balanced to meet or exceed Leybold vibration specifications

- The pump is run overnight on test

- Leak tested to 1 x 10^-10 mbar l/s

- Final vibration data sheet provided with each pump

- Every pump is refurbished to like new condition

- We stock new OEM Leybold rotors, stator blades, stator rings, shafts and more. We have every part needed to refurbish your pump to like new no matter what condition your pump is currently in.

Technical Data:

| Technical Data | TURBOVAC 1100 C | ||

|---|---|---|---|

| Connection Inlet DN | 160 ISO-K | 200 ISO-K | 250 ISO-K |

| Connection Outlet DN | 63 ISO-K | 63 ISO-K | 63 ISO-K |

| Pumping speed N₂ | 710 l/s | 830 l/s | 1050 l/s |

| Pumping speed Ar | 660 l/s | 760 l/s | 980 l/s |

| Pumping speed He | 650 l/s | 750 l/s | 850 l/s |

| Pumping speed H₂ | 520 l/s | 600 l/s | 630 l/s |

| Gas throughput N₂ | 6.5 mbar l/s | 6.5 mbar l/s | 6.5 mbar l/s |

| Gas throughput Ar | 6.5 mbar l/s | 6.5 mbar l/s | 6.5 mbar l/s |

| Gas throughput He | 8.0 mbar l/s | 8.0 mbar l/s | 8.0 mbar l/s |

| Gas throughput H₂ | 9.0 mbar l/s | 9.0 mbar l/s | 9.0 mbar l/s |

| Compression ratio N₂ | > 1 x 10⁷ | > 1 x 10⁷ | > 1 x 10⁷ |

| Compression ratio Ar | > 1 x 10⁷ | > 1 x 10⁷ | > 1 x 10⁷ |

| Compression ratio He | 3 x 10⁴ | 3 x 10⁴ | 3 x 10⁴ |

| Compression ratio H₂ | 1 x 10³ | 1 x 10³ | 1 x 10³ |

| Ultimate pressure | < 3.0 x 10⁻¹⁰ mbar (<2.3 x 10⁻¹⁰ Torr) | < 3.0 x 10⁻¹⁰ mbar (<2.3 x 10⁻¹⁰ Torr) | < 3.0 x 10⁻¹⁰ mbar (<2.3 x 10⁻¹⁰ Torr) |

| Max. foreline pressure for N₂ | < 1.0 x 10⁻¹ mbar (7.5 x 10⁻² Torr) | < 1.0 x 10⁻¹ mbar (7.5 x 10⁻² Torr) | < 1.0 x 10⁻¹ mbar (7.5 x 10⁻² Torr) |

| Recommended foreline pump | TRIVAC D 65 B / SCROLLVAC SC 15/30 D | TRIVAC D 65 B / SCROLLVAC SC 15/30 D | TRIVAC D 65 B / SCROLLVAC SC 15/30 D |

| Nominal rotation speed | 30000 rpm | 30000 rpm | 30000 rpm |

| Run-up time | 9 min | 9 min | 9 min |

| Max. power consumption | 400 W | 400 W | 400 W |

| Power consumption at ultimate pressure | 300 W | 300 W | 300 W |

| Admissible ambient temperature | 10 to 55 °C / 50 to 131 °F | 10 to 55 °C / 50 to 131 °F | 10 to 55 °C / 50 to 131 °F |

| Cooling standard | Water | Water | Water |

| Cooling optional | Air | Air | Air |

| Cooling water connection | 10 mm hose nozzle | 10 mm hose nozzle | 10 mm hose nozzle |

| Cooling water consumption | 24 to 60 l/hr | 24 to 60 l/hr | 24 to 60 l/hr |

| Permissible cooling water pressure | 3 to 7 bar | 3 to 7 bar | 3 to 7 bar |

| Permissible cooling water temperature | 10 to 30 °C (50 to 86 °F) | 10 to 30 °C (50 to 86 °F) | 10 to 30 °C (50 to 86 °F) |

| Weight | 22 kg (48 lbs) | 22 kg (48 lbs) | 22 kg (48 lbs) |

| Ordering Information | TURBOVAC 1100C |

|---|---|

| DN 160 ISO-K / DN 63 ISO-K, water cooled (newer style) | 800150V0030 |

| DN 200 ISO-K / DN 63 ISO-K, water cooled (newer style) | 800150V0031 |

| DN 250 ISO-K / DN 63 ISO-K, water cooled (newer style) | 800150V0032 |

| DN 200 ISO-K / DN 63 ISO-K, water cooled | 89483 |

| DN 250 ISO-K / DN 63 ISO-K, water cooled | 89480 |

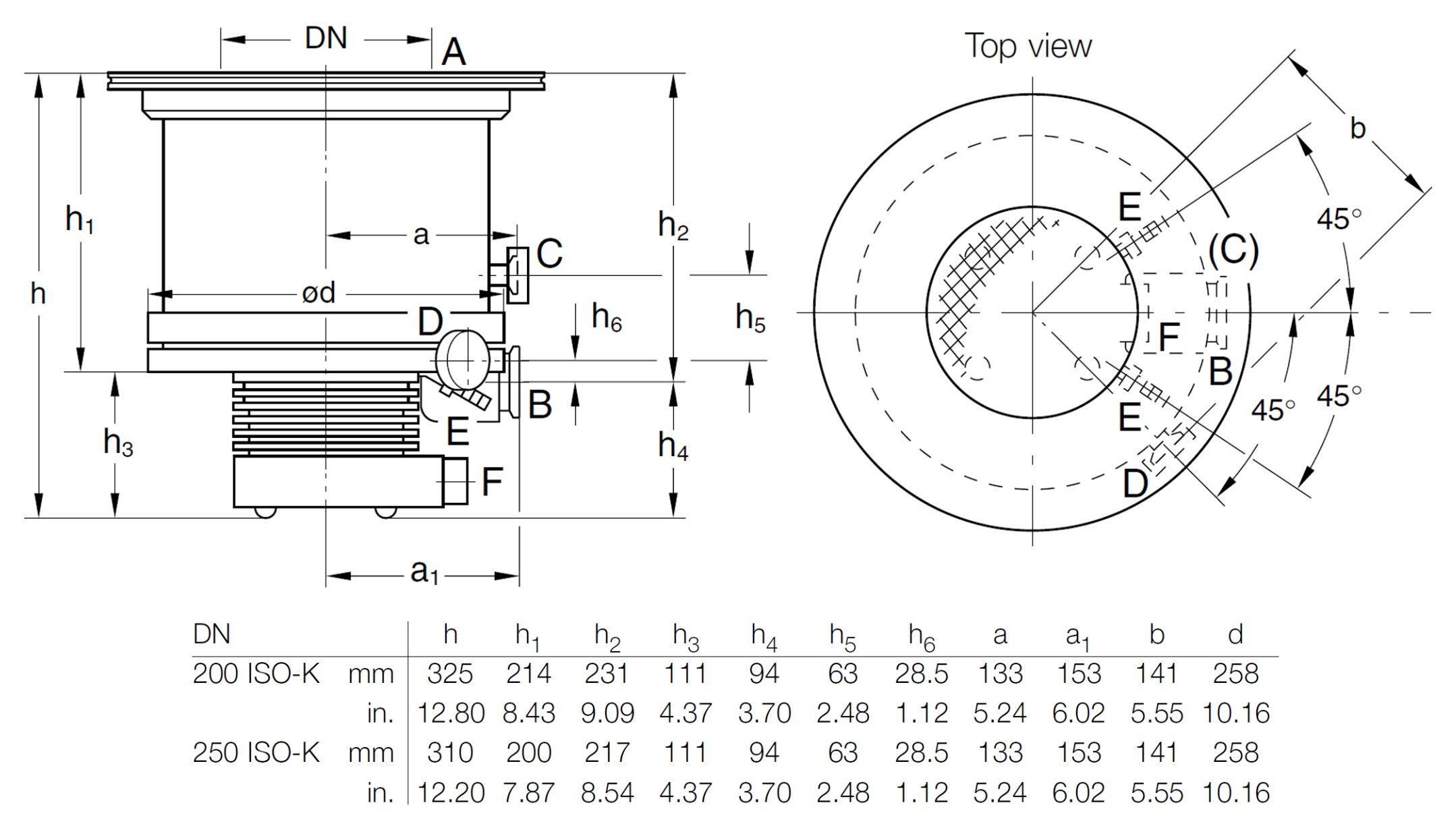

Leybold TURBOVAC 1100C Dimensional Drawing:

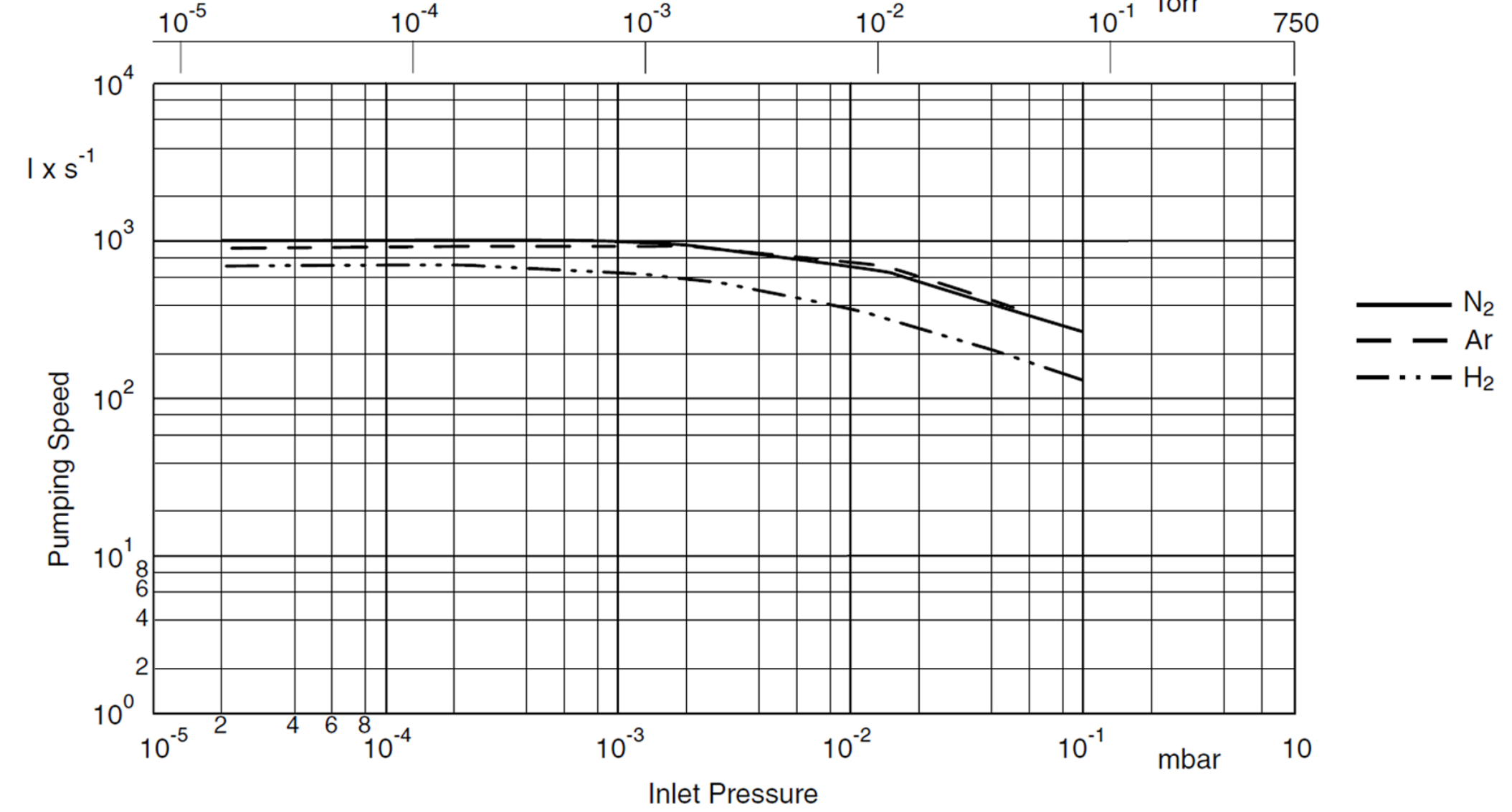

Leybold TMP 1100C Pumping Speed:

Leybold Vacuum TURBOVAC Classic Line Product Information